friction stir welding

(fsw)

In 2015, SBB was the first manufacturer in Canada to use this innovative process for mass production. Since then, we have forged in-depth expertise in this technology in Quebec, and have obtained accreditation from Alstom Transport.

Acquiring this skill allows us to meet a wide range of high quality welding needs for various uses:

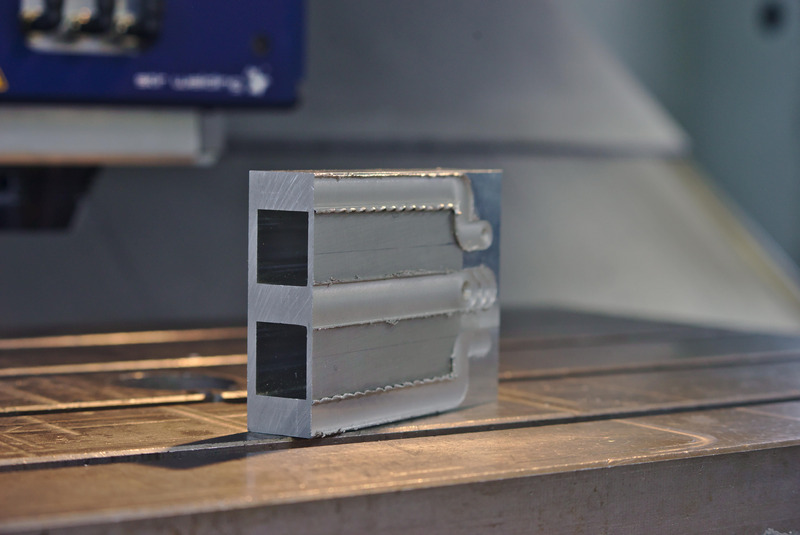

- Welding of extrusions

- Welding of castings

- Welding of parts made of non-fusion weldable materials, up to 12mm thick

The company chose to invest in this technology because it not only has great potential for automation and productivity, but also many benefits for customers:

- Improved mechanical properties of the assemblies

- High resistance and sealing of the weld

- Better predictability of workpiece final measurements

- Gain in lightness of the parts

- Increased life of the products

- Aesthetic result

Welding of foundry aluminium or dissimilar materials, such as aluminium & copper or aluminium & steel, is now greatly facilitated, while significantly reducing the risk of distorsion.

In addition, the method provides employees with a safer work environment free of the radiation and toxic fumes that usually accompany GMAW welding. Therefore, the production can be qualified as « clean ».

Our Production and Engineering Departments are available to discuss your projects that require innovative welding and high performance results.