Mechanical and

structural tests

Our ERS tower components are regularly tested according to the IEEE 1070-2006 guide and the IEC 61284 standard. In addition, they have been designed according to various applicable national standards and tested at their ultimate capacity during different tests.

Most of the tests performed on components have been witnessed or validated by independent firms or conducted under the supervision of customers during the Factory Acceptance Tests (FAT) at the end of the manufacturing cycle.

All the test results meet the IEEE 1070 criteria and, in most cases, surpass them.

IEEE 1070 tests include:

- Compression of sections

- Bending of sections

- Torsion of sections

- Combined Compression and bending of sections

- Ultimate bending - bolts / welds

- Load test on Guy Wires attachment (Universal Bracket)

- Ultimate capacity test on bolt and nut assemblies

- Buckling test on sections

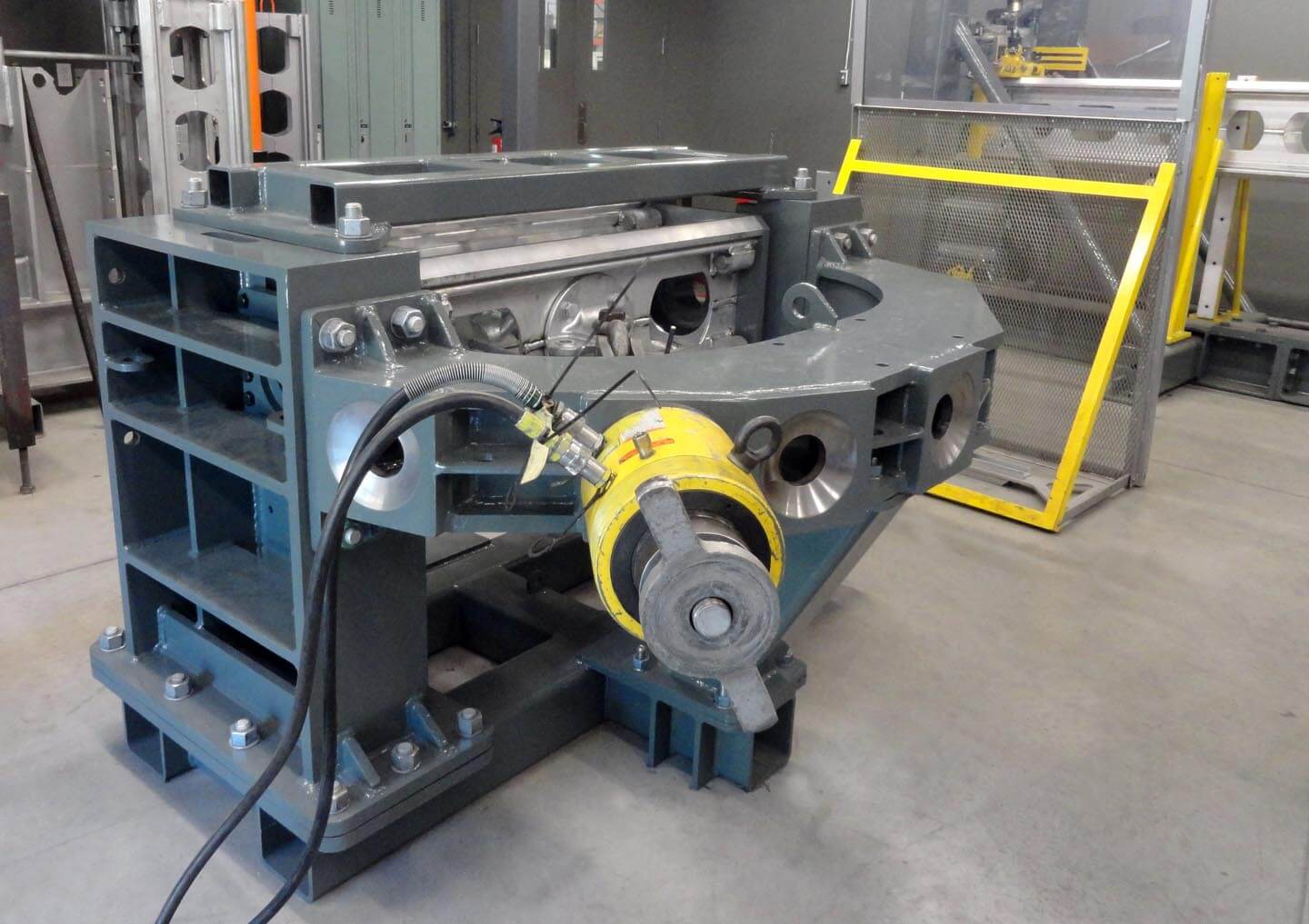

- Compression test on the Articulated Base

- Transverse test of the Articulated Base

- Capacity validation test

- Dimensional test

Ultimate Compression Test - École Polytechnique de Montréal

Ultimate Compression Test - École Polytechnique de Montréal

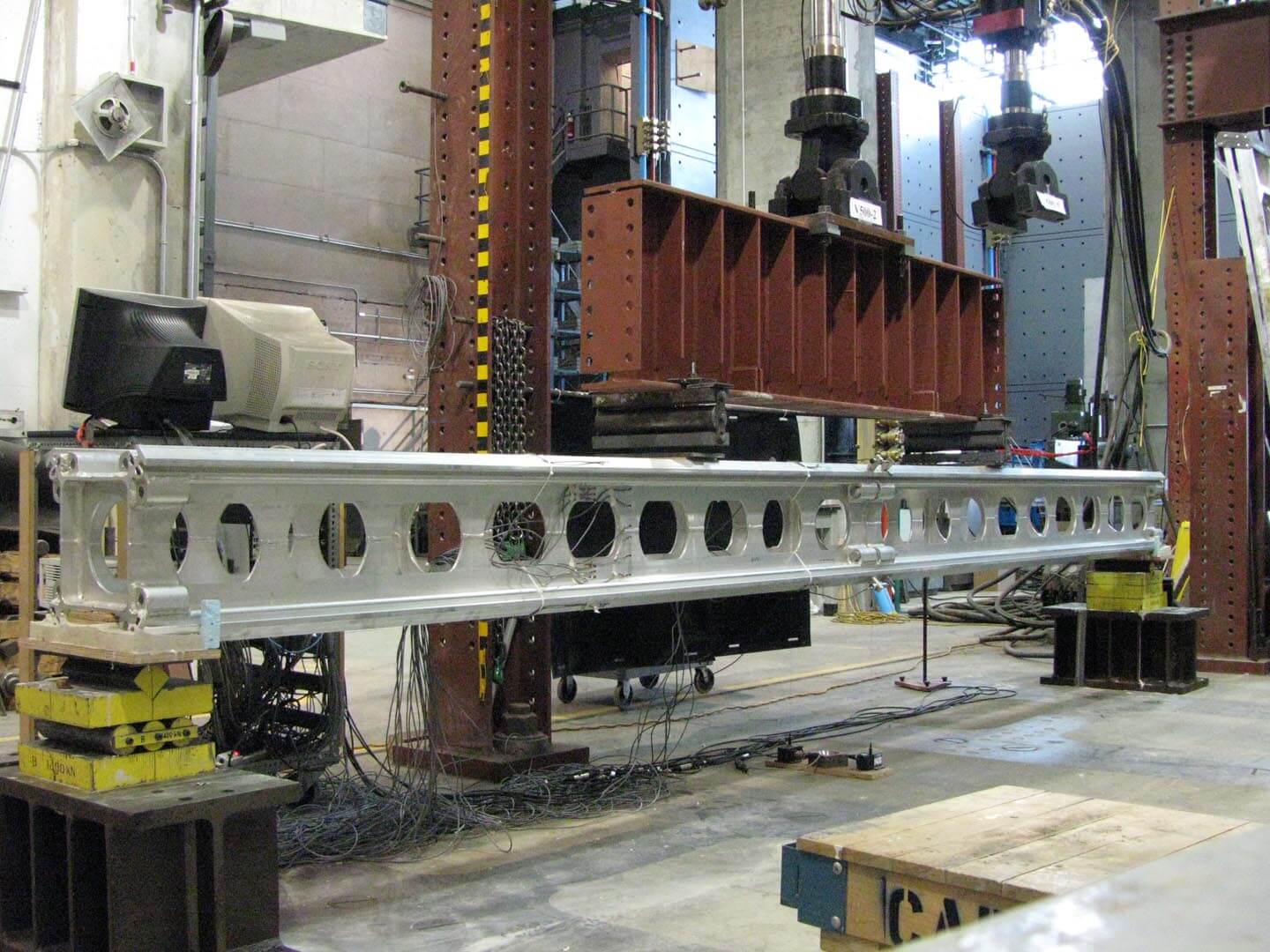

Bending test - École Polytechnique de Montréal

Bending test - École Polytechnique de Montréal

Bending test witnessed by customers - SBB Head office

Bending test witnessed by customers - SBB Head office

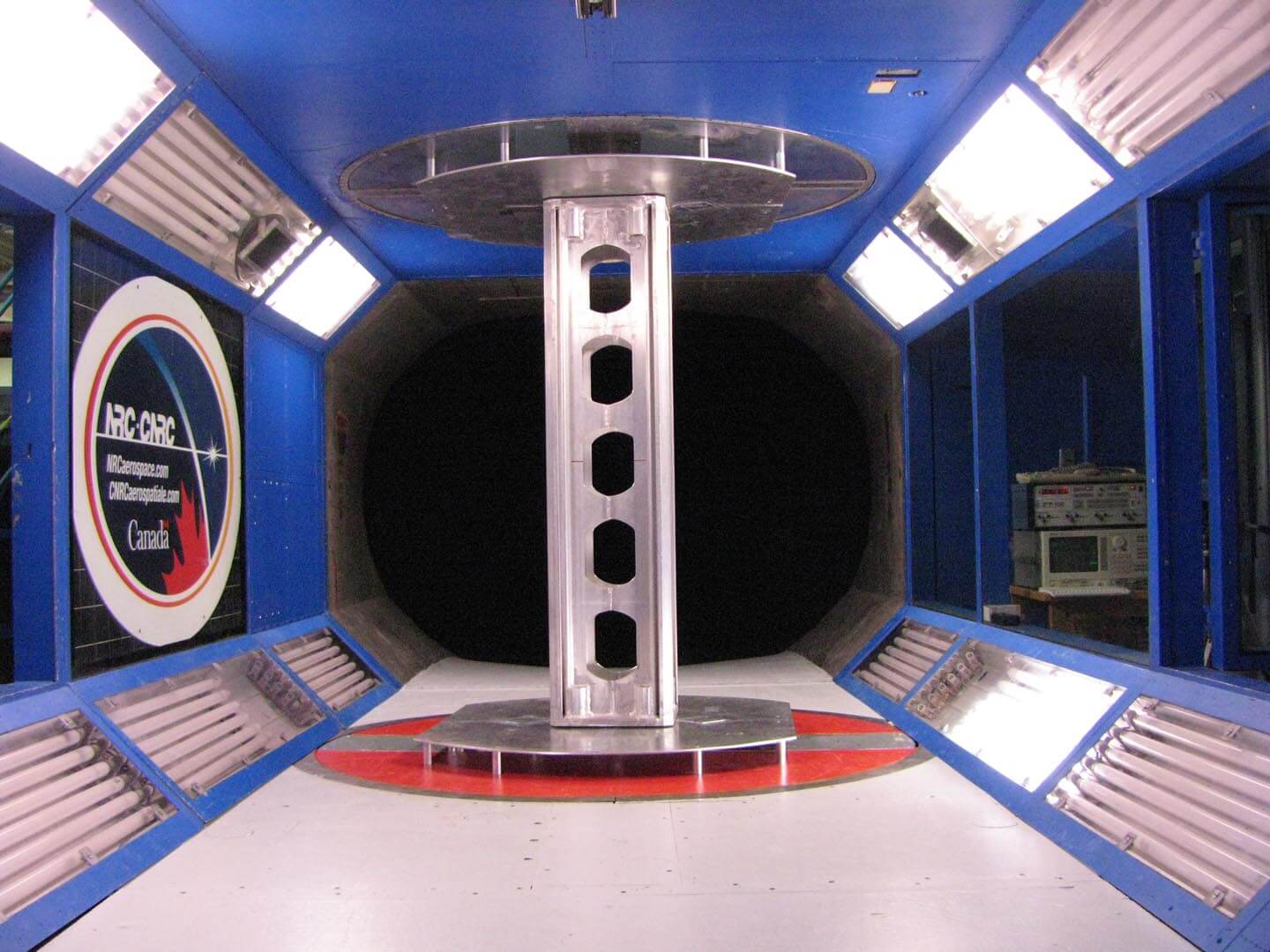

Wind Tunnel Test - NRC

Wind Tunnel Test - NRC

Buckling Test - SBB Head office

Buckling Test - SBB Head office

Universal Bracket Test - SBB Head office

Universal Bracket Test - SBB Head office